FairWeigh System

- Yiannis Ampatzidis, Matt Whiting, Mark De Kleine

- Sep 28, 2015

- 1 min read

We have created a portable harvest system –FairWeigh- that saves growers money and improves payroll accuracy/fairness, worker safety, and fruit quality.

FairWeigh accomplishes this without impeding the current harvest process by 1) precisely weighing the fruit each picker has picked, 2) accurately crediting the weight of harvested fruit to the individual picker, and 3) saving all data in a format that is easily imported to payroll software. This overcomes problems associated with growers significantly over-paying for harvested fruit by piece rate and will vastly improve payroll data entry.

The FairWeigh product is unique in its ability to: 1) accurately credit pickers for the fruit they have harvested in the field without impeding or altering the harvest process, 2) streamline data entry to payroll, 3) incorporate additional hardware to provide real-time tracking of harvest, yield mapping, and traceability, and, 4) generate precise and reliable harvest efficiency data.

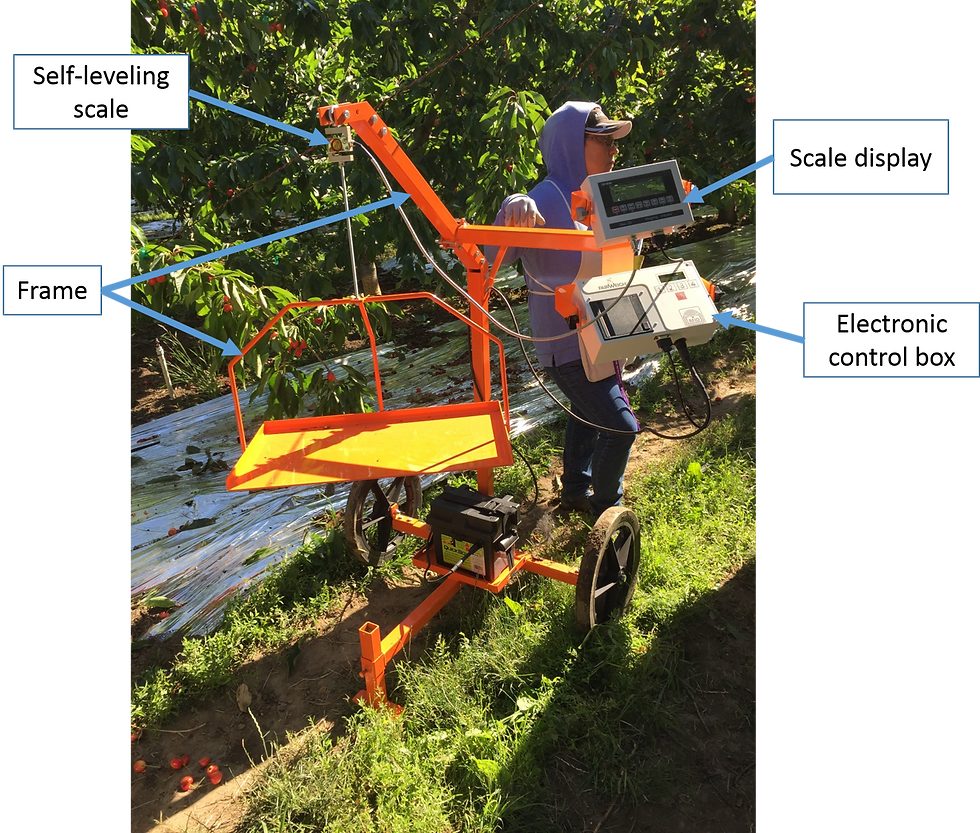

The FairWeighTM system comprised of three key elements: 1) a self-leveling scale, 2) electronic control box, and 3) a frame that supports all hardware. The electronic control box includes (Fig. 2): (i) a RFID reader, (ii) a LCD display, (iii) a thermal printer (prints a receipt for the pickers and the final report), and (iv) a GPD module (optional). RFID tags, containing unique ID numbers, embedded within rubber wrist bands, are worn by pickers. This system can read a picker’s ID (RFID bracelet), measure the weight of fruit, and record the time and location (optional) of every fruit transaction.

For more information: http://fairweighs.com

FairWeigh in the news: Good Fruit Grower 1, Good Fruit Grower 2, RFID Journal

Comments